Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

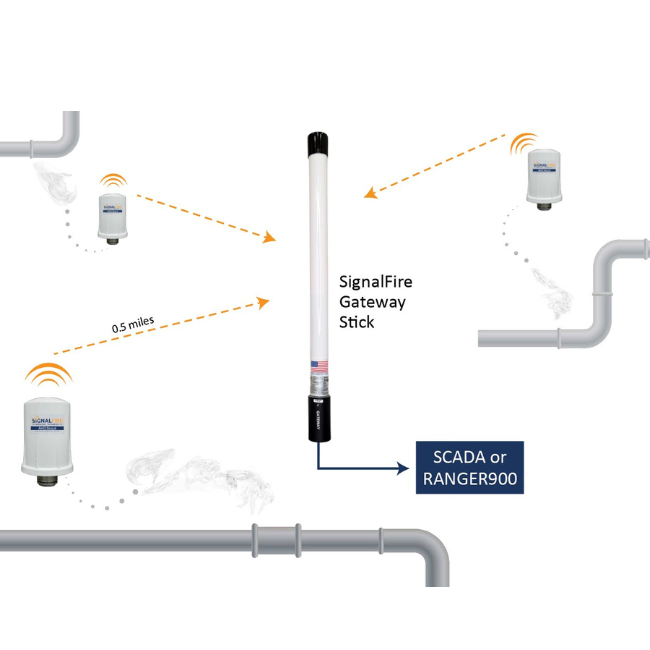

Configuring a wireless sensor network requires specifying various parameters including reporting frequency, device name, sensor scaling, Modbus addressing, etc. Often, application changes prompt modifications in network specifications.

Configuring a wireless sensor network requires specifying various parameters including reporting frequency, device name, sensor scaling, Modbus addressing, etc. Often, application changes prompt modifications in network specifications.

Many wireless sensor control systems require users to physically change settings by plugging computers into end devices or pushing local buttons. In addition to being labor intensive, this work is dangerous when accessing devices in remote and hazardous locations.

After a SignalFire telemetry system is working, operators can change settings or conduct diagnostics remotely through the use of a SignalFire Ethernet Interface Module and SignalFire Toolkit.

The Ethernet Interface Module permits a direct connection of the SignalFire Wireless Mesh Network to an Ethernet Network, providing access to Modbus TCP and the diagnostic features of the system. Technicians just need to access the IP address to configure changes to a SignalFire Remote Sensing System using the SignalFire Toolkit.

For example, to access the Gateway diagnostics remotely:

An Ethernet Interface Module also brings register data contained in the Gateway to field operators via local area network (LAN), Internet, or a cellular modem.

SignalFire Ethernet Interface Module also enables the configuration and calibration of a HART® transmitter using manufacturer’s software such as PACTware™. As with accessing the Gateway, users just point at the IP address and launch PACTware on their computer without the need for a serial connector. Once interfaced with a HART device, operators gain complete insight into its parameters, health, and condition.

The SignalFire 900Mhz protocol tunnels the HART information much faster than other protocols. In fact, the efficiency of the interaction is comparable to a technician physically connecting a HART modem interface directly on the device. The manufacturers DTM (device type manager) software can, therefore, be utilized in a practical, safe, and efficient way without operators working in a hazardous environment.

Find out how an Ethernet Interface Module integrated with a SignalFire Gateway Stick to enable plant operators at a pizza production plant to manage flour usage by personal computers and other devices. Download the story here.

Download information on SignalFire Ethernet Module here.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields