Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

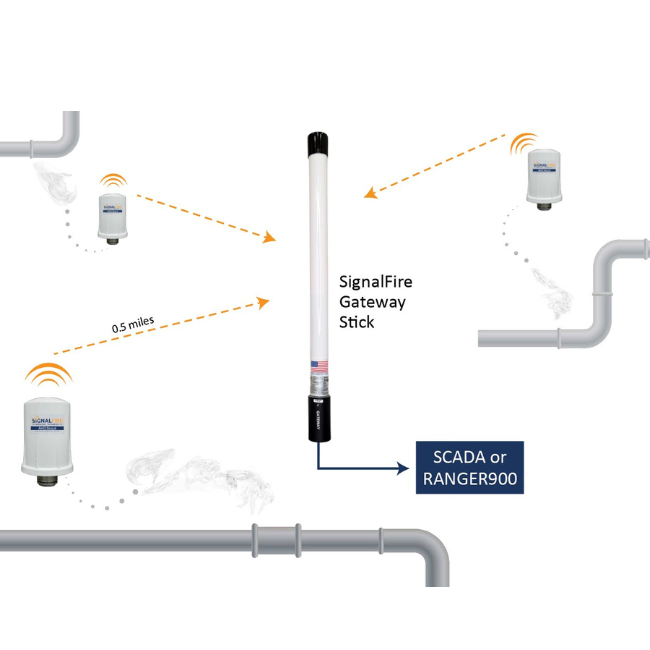

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

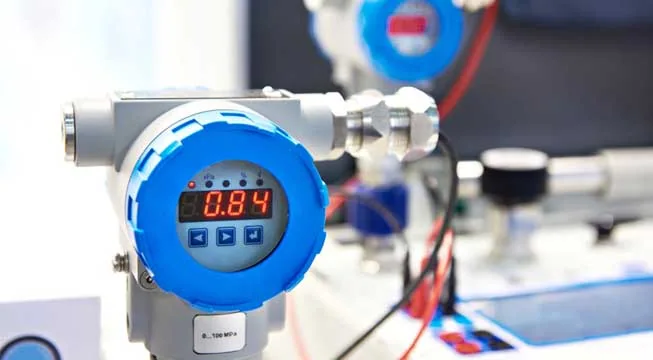

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

Monitoring pipeline corrosion is important to determine the ongoing degradation of pipes and prevent leaks, process challenges, and failures. The new pipeline corrosion monitoring solution from Axess-Corrosion combines the RANGER IoT transmitter with a sacrificial sensing probe to provide data and alarms on pipeline corrosion levels.

In operation, the probe, which is inserted into the pipe, is equipped with a depleting “sacrificial” membrane and can detect corrosion or erosion of the membrane as finite as 0.0001”. By measuring depletion rate, the probe provides feedback on the predicted rate of corrosion on the pipeline wall. It is critically important to oil producers to receive feedback about the performance of the expensive, corrosion-inhibiting chemicals and if the dosage rate is optimal.

Utilizing the latest cellular LTE CAT M1 with MQTT/SparkPlug technology for remote locations, the battery-powered RANGER cellular transmitter powers the corrosion sensors, then gathers and transmits data from the sacrificial probe to the cloud for remote monitoring control, and alarm from any web browser including mobile devices. By publishing over cellular networks using MQTT and TLS security, the RANGER IoT cellular transmitter is isolated from local area networks to offer a more secure connection.

Operators can access data on pipeline corrosion status in real-time from a computer or a mobile device or by integrating the measurement over MQTT communication into their own data historian. The RANGER is also programmable to provide alarms by text or emails to specific personnel and buffers up to 200,000 time-sampled measurements.

As many pipelines are located in isolated areas, the RANGER cellular transmitter addresses the need for monitoring isolated measurements or ‘lone rangers’ where it is cost-prohibitive or challenging to simply get a reading from a sensor.

“O&G operators spend millions of dollars a year on chemicals to minimize corrosion. With the RANGER incorporated within Axess’ pipeline corrosion monitoring solution, operators gain awareness of pipeline integrity with minimal infrastructure to address issues and optimize the use of chemicals,” notes Sandro Esposito, VP of Sales & Marketing for SignalFire. “The RANGER also removes barriers in monitoring pipelines in isolated areas by delivering sensor data to the cloud. We have thousands installed in remote and harsh environments.”

“The RANGER provides Axess with the perfect solution for remote operating sites and clients that wish to monitor corrosion by exception,” stated Roland Anderson, CEO of Axess-Corrosion. “The data sent by the RANGER also integrates seamlessly to our Hive software and alarms are set for metal loss thresholds and trends. In addition, Axess has also integrated permanent wall thickness sensors, thermowells and injection pump and tank data – all sent to Hive via the RANGER.”

For more information about the RANGER, visit RANGER – SignalFire Wireless Telemetry (https://www.signal-fire.com/) or contact info@signal-fire.com

Axess designs, manufactures and delivers the safest monitoring solutions based on a client’s application. The company is uniquely positioned to supply products and services that complement, integrate and support projects from the design stage, through maintenance and data retrieval and analysis. Axess – Corrosion Monitoring Solutions

SignalFire Wireless Telemetry designs and manufactures industrial wireless sensors and radios to enable reliable and cost-effective measurements without the use of wires. These products are robust and certified for hazardous locations with a built-in secure communication protocol that enables robust, long-distance wireless communication connecting multiple devices together in challenging outdoor environments. The company’s objective is to provide users with the solution they need to digitally transform their operations with the use of existing or new sensors without wires.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields