Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

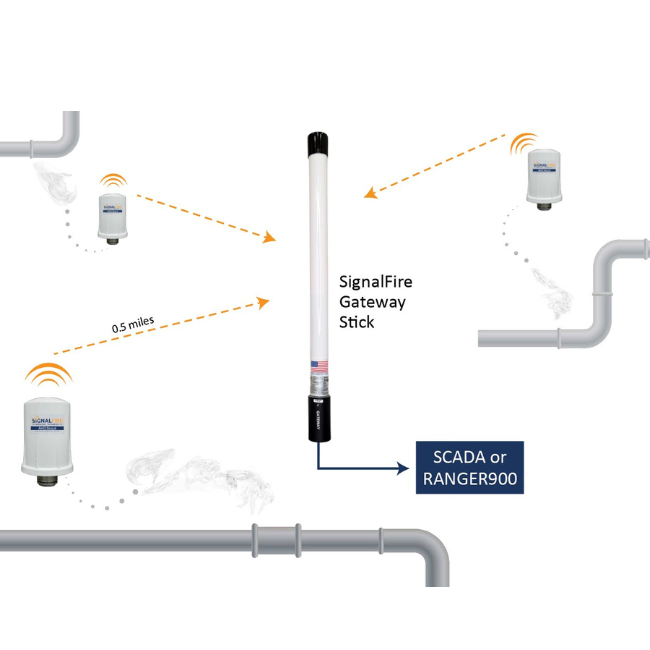

Remote monitoring and control systems rely on radio communications to integrate their devices (sensors, nodes, Gateways) to a wireless network in the transmission of data. A large number of radio-based telemetry systems use communication networks based on a 2.4 GHz frequency band. For example, Zigbee, Wireless Hart, ISA 100 and other 802.15.4 systems operate in the 2.4 GHz wireless frequency spectrum.

While ideal for short range building and plant environments, 2.4 GHz systems have limitations when performing in outdoor applications. A lower frequency is much better and a 915 MHz system provides a more reliable data transmission over longer ranges in more challenging environments.

The operating range or distance over which the wireless system must perform determines the best frequency band. When assessing the use of a 2.4 GHz or 915 MHz system, consider the following factors:

In the US and Canada, 915 MHz systems can transmit powers up to 1 Watt and have antennas that can double that range (+6 dB). While 2.4 GHz systems can operate at the same power levels in the US and Canada, most do not exceed the global requirement of 0.1 Watts. Global restrictions on 2.4 GHz frequency further limit performance by measuring radiated power – no antenna gain is permitted for a full power (0.1 Watt) system in most countries.

With operating parameters being equal, a 915 MHz system offers about 2.6 times the range of a 2.4 GHz system. In most cases, the 915MHz supports longer range between nodes, beneficial for wireless sensor control networks that cover large geographic areas of hundreds of square miles.

Most wireless sensor control systems are subject to two types of interference that disrupt the communication signal: physical and electromagnetic.

Physical Interference

Figure 2: Results of Wet Foliage Test conducted with SignalFire telemetry system operating on two different frequencies.

Figure 2: Results of Wet Foliage Test conducted with SignalFire telemetry system operating on two different frequencies.Both frequencies use standard techniques to manage radio interference. Choice of methodology depends on system design.

Data rate does significantly impact range. Most 2.4 GHz systems transmit at 200 – 500 Kbits/sec. A SignalFire Remote Sensing System operating at 915 MHz transmits at 10 Kbits/sec which is sufficient for telemetry applications but not for applications like live video feed. Doubling the data rate causes a 3 dB loss in link budget. When compared to a 200k bit/sec system, the SignalFire Telemetry System has an advantage of about 12 dB (6 dB= a doubling of range).

No one frequency provides the perfect solution in supporting the communications of a wireless telemetry or mesh network. While working well in building and plant environments at ranges measuring in tens of meters, a 2.4GHz frequency poses limitations in longer ranges and under certain outdoor conditions. A 915 MHz frequency offers a more reliable data transmission platform for outdoor applications where data must be reliably transmitted hundreds to thousands of meters under different weather conditions. The choice ultimately depends on the application, environment and how much data is transmitted.

Read about the Factors in Determining the True Range of a Wireless Sensor Control Systems

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields