Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

In challenging environments where it is too time-consuming, costly, or unsafe for operators to manually operate assets, equipment is best shut down remotely. For example, an oil field may have a tank that collects oil and/or water from several wells located several hundred yards to several miles away from the tank battery. When the tank becomes full, wells must be shut down to prevent overflow. Because of the oil-field layout, the decision to shut down a well is optimally controlled from a remote tank site. Increasingly, oil and gas operators are implementing remote shutdown systems to avoid spills or other adverse events from impacting well pad operations.

A long-range wireless telemetry remote shutdown system with fail-safe logic is ideal to monitor inputs and generate control commands autonomously to shut down wells when tank levels exceed preprogrammed levels. For example, the SignalFire Remote Shutdown System (RSD) shuts down assets remotely with the fail-safe logic necessary for wireless operation of critical systems. The RSD is configurable with either a PLC or Gateway that can monitor inputs and generate remote shutdown commands.

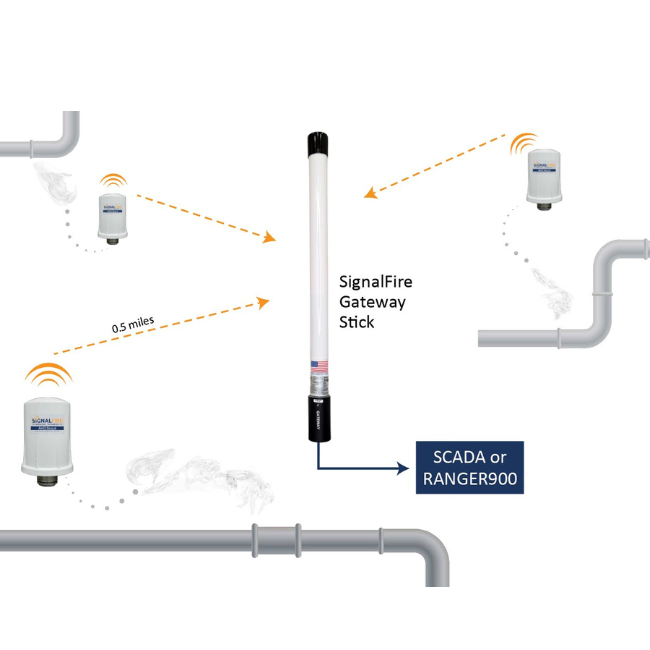

The diagram below depicts the configuration of a PLC-controlled system. In this configuration, a local PLC at the tank battery makes the decision to shut down the remote well sites. Tank level information (switch, level sensors, pressure sensors, etc.) is connected to a local PLC. The PLC monitors the sensor information and determines whether or not the tank is in an alarmed state. Information is sent to the gateway via a Modbus RS 485 connection for transmission to the remote nodes at the well sites.

With the PLC making the commands, the Gateway simply ensures reliable communications to the remote nodes. Additionally, the remote node’s two digital input channels can monitor the well site’s state (on or off) and transmit this actionable information back to the Gateway so the PLC can monitor the well site’s remote state.

A Gateway also can be configured to monitor and control remote well sites as a standalone system, using a PLC to offload sensor input. In the diagram above, a SignalFire Gateway-In-A-Stick is configured to update the remote shutdown nodes based on the status of tank levels as received from tank sensors. For example, a radar-level sensor in the tank would send information wirelessly to the Gateway-In-A Stick, which would be configured to update the remote nodes appropriately.

A sample logic command can request that if tank level from sensor A is greater than X.X feet, set relay B on remote node C to be de-energized. Following this logic, the Gateway would send control commands via a wireless link to a Remote Shutdown Modbus-in-A-Stick that automates this action without the need for long, costly conduit runs.

Both the PLC and Gateway-based remote shutdown systems support a large number of wireless sensors. In addition to being used extensively in upstream oil and gas applications, the RSD systems are ideal for water-tank control and industrial situations where tank monitoring and pump control are necessary.

For detailed specifications on the SignalFire Remote Shutdown System, visit SignalFire’s website here.

Download our article on Wireless Remote Shutdown Systems here.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields