Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

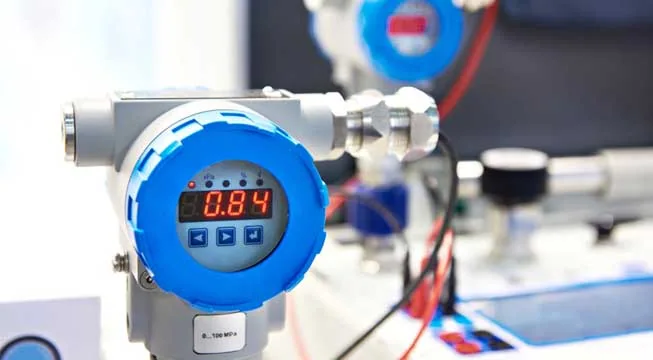

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

SignalFire Sentinels Monitoring

Tubing and Casing Pressure

Hudson, Ma – The SignalFire wireless system is ideal for monitoring Tubing and Casing pressures in Upstream Oil and Gas fields. “SignalFire offers several options for wireless monitoring of well pad tubing and casing pressures depending on the specific requirements of the operator” said Scott Keller, CEO of SignalFire Telemetry. The principle advantages of wireless Tubing and Casing Pressure Monitoring are:

“SignalFire’s Open Architecture permits the integration of a wide variety of sensors, transmitters, and actuators using industry standard interfaces. Tubing and Casing pressures, Heater-Treater Temps, Flare Temps, Tank Levels, Flows, Well Shut In, RTU’s, and other oilfield measurements and controls can all be seamlessly integrated into a single system using the SignalFire Telemetry’s equipment” Keller added. “Give us a call and find out for yourself.”

SignalFire Telemetry is the developer of the SignalFire Telemetry System, an innovative long range mesh networking technology specifically designed for challenging, large-scale environments characterizing industries such as oil and gas, agriculture, forestry, water systems, and public infrastructure. Unlike other systems the SignalFire System is an Open Architecture that permits customers to integrate the sensors and actuators of their choice rather than the ones chosen by their wireless vendors. Many SignalFire Systems are rated Class 1 Div. 1 and can power sensors from internal batteries or Class 1 Div. 1 solar systems.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields