Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

In determining the amount of available energy in hydroelectric dams, water level height at the reservoir must be continuously monitored. When the need arose to replace an aging hydrostatic water level sensing system at a dam, the SignalFire Remote Sensing System (SFRSS) offered a more cost efficient and reliable solution for the remote monitoring of hydroelectric dam levels.

The previous level sensing system connected to the power station via a hard-wired cable. In addition to having problems with ground faults, the cabling of the wired system was prone to lightning strikes that would damage the entire network. The installation of another wired level sensing system from the dam to the powerhouse posed physical challenges and was costly because meeting the requirement for “redundancy” would require a second system.

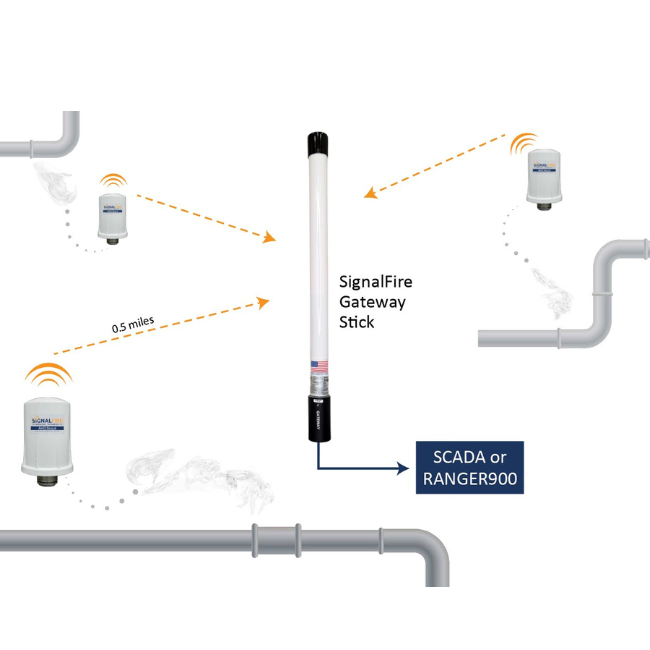

As a wireless system, the SRFSS does not require cabling, eliminating the risk of failure due to lightning strikes and ground faults. Consisting of a gateway and remote nodes, the wireless sensor control system operates on an adaptive radio network to seamlessly integrate with the hydrostatic transmitters and send level data to a remote programmable logic controller located at the power station.

With a range of approximately three miles, the network with redundant communications link is both self-installing and self-configuring, so it immediately starts once the settings, address and parameters for the individual components are entered.

For more detailed information, download the application note on the Wireless Monitoring of Hydroelectric Dam Levels.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields