Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

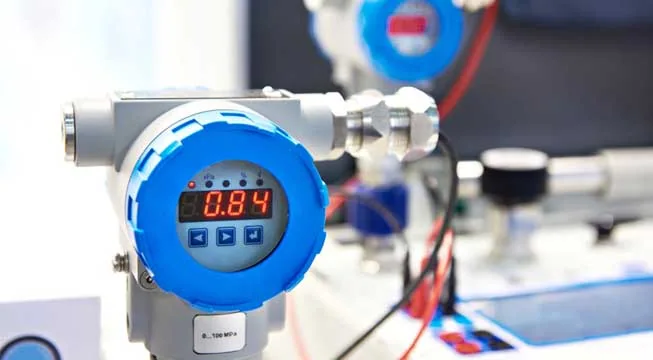

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

Food manufacturing facilities, agricultural farms, chemical plants and other industrial plants use tanks and silos for storage of necessary processing ingredients or end product. Monitoring the levels of these steel storage vaults is essential for inventory control and safety. But, tank level monitoring is often a challenging task.

Containing hazardous materials or situated in inconvenient and remote locations, these storage chambers pose potential dangers and difficulties when taking manual readings. Even as wired sensor systems replace manual methods for tank level monitoring, cabling requirements, environmental conditions, multiple sensing requirements, and topography can present challenges depending on the application.

Wireless sensor control systems offer many advantages over wired systems that can improve the operational efficiency in monitoring tanks and silos while reducing costs. They are less susceptible to lightning strikes, eliminate cabling requirements, work in very remote locations, and interface with virtually any type of sensor. In fact, tank level monitoring is perhaps the most common application optimized with wireless sensor networks.

While known throughout the oil & gas industry for providing a reliable and cost-effective solution for monitoring tank farms, the SignalFire Remote Sensing System is used in other industries such as farms, food processing plants and rail cars for wireless level sensing.

Here are some application stories that provide insights on how the SignalFire tank telemetry helped a variety of industries automate tank level monitoring with wireless and remote data acquisition capabilities.

A regeneration facility increased worker safety and efficiency by automating measurement of hazardous liquids in rail cars with the SignalFire Remote Sensing System. Previously, technicians used a measurement stick to determine the levels of sulphuric acid in rail cars, exposing them to acid fumes.

Tortilla Chip Manufacturer Automates Management of Cooking Oil in Storage Tanks

A SignalFire Remote Sensing System configured with a Pressure Scout offers a more accurate and safer alternative to manually gauging tanks to estimate volume in determining when to order new supplies of cooking oil and dispose of the wasted stock.

Wireless Monitoring of Farm Silo Levels

As farmers look to operate more profitably, many are adopting wireless technology to better track, control, and connect different operations. Whether a large dairy, small poultry or diversified crop farm, wireless sensor monitoring and control systems can automate the remote management of silo levels. More than automating data collection, these wireless telemetry systems are configurable to shut down operations or send an alert when reaching a threshold. Collected data is downloadable into analytics software for better asset management, such as calculating and analyzing feed storage costs in silos.

To read about more SignalFire applications, visit: https://www.signal-fire.com/applications/ .

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields