Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

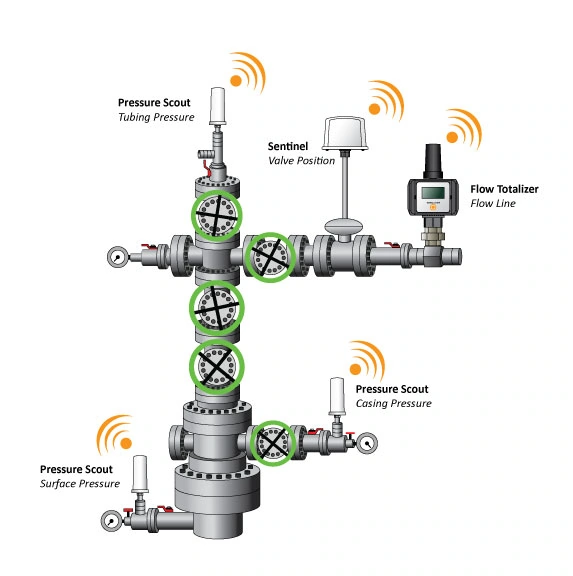

By monitoring tubing and casing pressures in oil and gas fields, operators can gain essential information about well safety and performance during oilfield production. Traditionally, dial gauges measured and monitored these pressures, with pumpers taking readings manually during daily or weekly rounds.

This traditional approach posed several challenges. The pumper must climb to the top of the tank or wellhead to read and record the data—a dangerous activity if emissions and other harmful vapors are present. Security risks, data inaccuracies, and expenses related to pumpers’ trucks and tools are additional disadvantages. Such issues prompted many companies to implement remote monitoring and control systems such as the SignalFire Remote Sensing System (SFRSS).

This traditional approach posed several challenges. The pumper must climb to the top of the tank or wellhead to read and record the data—a dangerous activity if emissions and other harmful vapors are present. Security risks, data inaccuracies, and expenses related to pumpers’ trucks and tools are additional disadvantages. Such issues prompted many companies to implement remote monitoring and control systems such as the SignalFire Remote Sensing System (SFRSS).

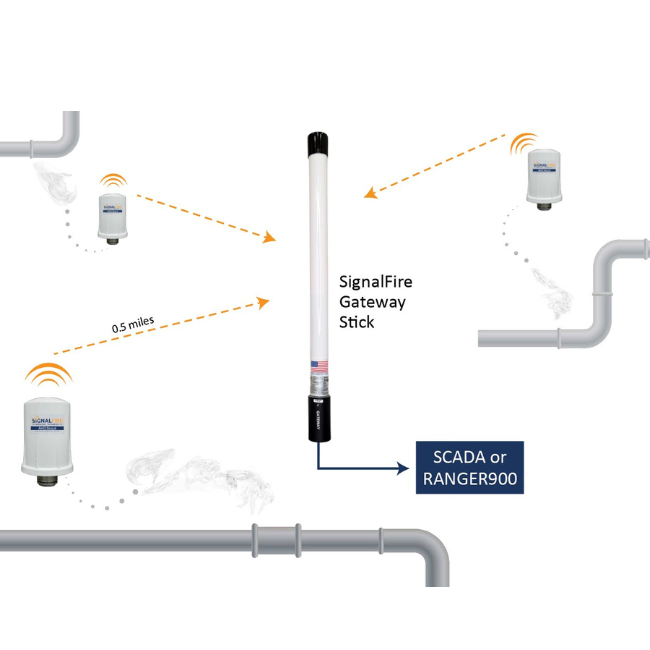

In addition to eliminating the need for manual data collection, the SFRSS provides up-to-the-minute, detailed information on wellhead pressures and can establish alerts for different measured parameters. In addition, the wireless telemetry system enables operators to track performance for multiple locations from one centralized control center or laptop.

Most remote monitoring and control systems use an independent digital pressure transmitter to send the electrical signal that represents the casing and tubing pressure. SignalFire developed the Pressure Scout, which integrates a pressure sensor, wireless node, and intrinsically safe internal battery in one package.

When used to monitor tubing and casing pressures, the Pressure Scout reads pressure status at a configured interval (every 5 seconds, 1 minute, 5 minutes,…). It also reports the status to a SignalFire Gateway, where a Modbus RTU or TCP interface makes the pressure data available. Using this data, operators can view and analyze current and long-term wellhead performance and discern trends. Simultaneously, the Pressure Scout is configurable for alarm reporting and provides rapid notifications when the pressure sensor detects a reading outside of set low or high thresholds. The diagram shows how the wireless measurement of pressure and flow transmit to a SCADA system that’s on the operator’s premises or in the cloud. A Flow Totalizer with display measures flow rates.

The Pressure Scout uses an internal intrinsically safe battery that powers the integrated pressure sensor and radio. This system has a long battery life. For example, a pressure-monitoring application requiring a 5-second sample interval for alarming, with a 1-minute reporting interval, will last 6 ½ years. The Pressure Scout also offers a local and remote zeroing capability. Operators can zero sensors by pushing a button while they’re in the field or remotely from the Gateway or home office.

Class 1, Division 1 certified, the Pressure Scout operates in challenging outdoor environments. It uses the low-frequency 915 MHz band, which is preferable to 2.4 GHz systems because it sustains signal strength through terrain, structures, or weather. Available in 11 standard pressure ranges up to 20,000 psi, units work in extreme temperatures ranging from -40°C (-40ºF) to 55ºC (176°F).

For additional information on the Pressure Scout, please visit https://www.signal-fire.com/pressure-scout/ or download the video at https://www.youtube.com/watch?v=DLd_q7kF0tY .

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields