Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

SignalFire Telemetry products connect you with crucial product and hardware data at any of your oil and gas operation sites—whether it’s a pump, pipeline, or storage tank.

SignalFire Telemetry devices install anywhere water asset monitoring is needed, whether it’s for collection purposes, treatment, or delivery.

SignalFire Telemetry devices can monitor key assets and can do it affordably, without any renovation or high-priced engineering costs. They install easily with no required cable or additional power. The data is available on your phone or computer and the cloud service can even output to your corporate system to integrate with the rest of your data and keep your operation running.

SignalFire Telemetry devices can monitor and manage water supplies and additives throughout the property, helping you avoid catastrophic shortages and keep your irrigation plan on track.

Avoid costly product loss in bulk storage tanks, terminals, and transportation movements. Whether calling for tank levels, gauge pressure, or even movement pumps or pipelines, SignalFire products can fill any monitoring gap throughout a facility.

Environmental fines for businesses are be frustrating and can bring business to a standstill until they’re worked out. No business wants to hurt the environment, and in competitive markets stopping production affects the bottom line and staff. But there are effective and affordable solutions with SignalFire Telemetry devices.

Expand visibility and control of your refinery or petrochemical processing facility without expensive renovations or redesigns. And do it with your current gauges and hardware. SignalFire telemetry devices are designed to work in harsh chemical environments and meet the strictest safety and security standards

No matter the size of your service map, monitoring remote assets ensures efficiency and keeps your operation in compliance. That’s how SignalFire devices can really help, offering the most affordable and effective monitoring solution that will monitor liquid, gas, electricity, and other assets.

Explore the diverse applications of SignalFire Wireless Telemetry Systems across different industries.

Access our latest brochures to explore comprehensive information about our products and services.

Easily find the sensors that are compatible with our systems on this dedicated page.

Explore a comprehensive collection of images showcasing our products, installations, and real-world applications.

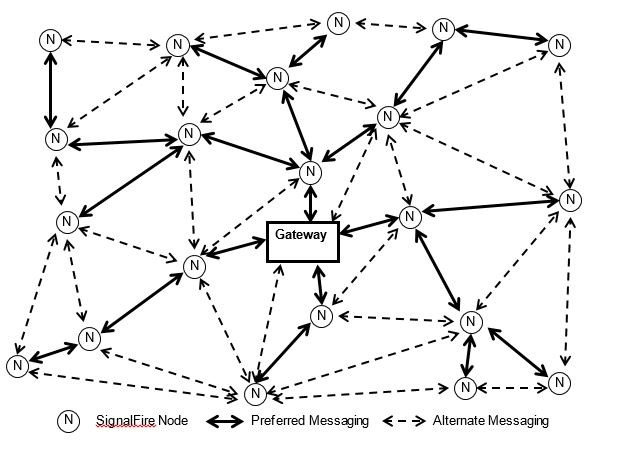

Shown is a configuration of Sentinel radio nodes in one network that tie into a single Gateway. The nodes gather data from sensors installed on tanks for transmission to the Gateway that formats it for accessibility by a PLC. Robust gateways can accommodate hundreds of transceiver inputs from field sensors, enabling the network to cover a large geographic range.

You asked, so we are answering some of your frequently asked questions about the SignalFire Remote Sensing System. For technical support, contact us at support@signal-fire.com or 978-212-2868 x2.

The SignalFire Remote Sensing System (SFRSS) is composed of radio nodes that power and extract data from sensors for transmission to a Gateway that serves as the central processing hub. The Gateway can support up to 240 Modbus slave addresses and, therefore, 240 SFRSS nodes.

It is essential to manage network traffic when determining the maximum size of the remote sensing system. Understanding network traffic helps dictate over-the-air configuration (OTA) and remote sessions using PACTware when working with a HART device.

The availability of outside communications (i.e., cellular, satellite, RS485, Ethernet) dictate the Gateway locations and drives the actual number of nodes. Typically, most of our customer’s installations operate between 3 and 75 modules.

While many wireless networking systems restrict sensor selection to one or two types, the SFRSS allows users to integrate many sensor types to monitor assets. The user chooses the best sensor for each application, and the SignalFire wireless system ties them together. SignalFire nodes commonly work with the following sensor types (interfaces shown in parentheses):

With the capability to integrate with various sensors simultaneously, the SignalFire Remote Sensing System can provide continuous status on different assets. For example, tubing and casing pressures as well as heater-treater temperatures, gas flare temperatures, tank levels, flow, well shut-in, RTUs and other oilfield measurements and controls can be seamlessly integrated into a single system using the SignalFire Telemetry equipment. Read about how remote sensing systems Monitor Tubing and Casing Pressures for Equipment Safety, Optimized Production.

Installation is easy as nodes automatically configure within a SignalFire mesh network. A mesh network allows wireless nodes to utilize neighboring nodes to relay or “hop” messages to a central location (Gateway).

Each node determines the “best path” to the Gateway based on information derived from nearby nodes. The message will get through as long as there is a communications path. The intuitiveness of the nodes allows the system to automatically adjust to changes so data can take alternative routes when necessary to its ultimate destination.

Shown is a configuration of Sentinel radio nodes in one network that tie into a single Gateway. The nodes gather data from sensors installed on tanks for transmission to the Gateway that formats it for accessibility by a PLC. Robust gateways can accommodate hundreds of transceiver inputs from field sensors, enabling the network to cover a large geographic range.

Get in Touch With Us and Tell Us About Your Toughest Monitoring and Control Challenges.

"*" indicates required fields

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.